Understanding Chip Inductors: A Comprehensive Guide

I. Introduction

In the realm of modern electronics, chip inductors play a pivotal role in ensuring the efficient operation of various devices. But what exactly is a chip inductor? This article aims to demystify chip inductors, exploring their definition, significance, and applications in contemporary technology. By the end of this guide, readers will have a comprehensive understanding of chip inductors and their importance in the electronic landscape.

II. Basics of Inductance

A. Definition of Inductance

Inductance is a fundamental property of electrical circuits, defined as the ability of a conductor to store energy in a magnetic field when an electric current flows through it. The unit of inductance is the henry (H), named after the American scientist Joseph Henry.

B. The Role of Inductors in Electrical Circuits

Inductors are passive components that resist changes in current. When the current through an inductor changes, it induces a voltage in the opposite direction, which can help stabilize the current flow in circuits. This property makes inductors essential in filtering, energy storage, and signal processing applications.

C. Comparison of Inductors and Capacitors

While both inductors and capacitors are passive components used in electronic circuits, they serve different functions. Inductors store energy in a magnetic field, while capacitors store energy in an electric field. This fundamental difference leads to distinct applications for each component, with inductors often used in power supply circuits and capacitors in timing and filtering applications.

III. What is a Chip Inductor?

A. Definition and Characteristics

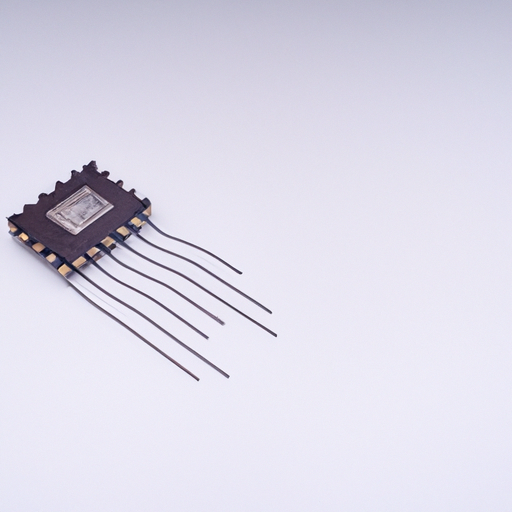

A chip inductor is a type of inductor that is miniaturized and designed for surface mounting on printed circuit boards (PCBs). These inductors are typically made from ceramic or ferrite materials and are characterized by their small size, high inductance values, and low DC resistance.

B. Differences Between Chip Inductors and Traditional Inductors

Unlike traditional inductors, which may be larger and require through-hole mounting, chip inductors are compact and designed for surface mount technology (SMT). This allows for more efficient use of space on PCBs, making them ideal for modern electronic devices where size and weight are critical factors.

C. Common Applications of Chip Inductors

Chip inductors are widely used in various applications, including power management circuits, RF (radio frequency) applications, and signal processing. They are commonly found in consumer electronics, automotive systems, telecommunications, and industrial equipment.

IV. Construction and Design of Chip Inductors

A. Materials Used in Chip Inductor Manufacturing

1. Core Materials

The core of a chip inductor is typically made from ferrite or ceramic materials, which provide high magnetic permeability and low losses. Ferrite cores are often used for their excellent high-frequency performance, while ceramic cores are favored for their stability and reliability.

2. Wire Materials

The wire used in chip inductors is usually made from copper or aluminum, chosen for their excellent conductivity. The wire is wound around the core to create the inductive element, and the number of turns affects the inductance value.

B. Design Considerations

1. Size and Form Factor

Chip inductors come in various sizes and form factors, allowing designers to choose components that fit their specific PCB layout and space constraints. The size of the inductor can impact its inductance value and current rating.

2. Inductance Value and Tolerance

Inductance values for chip inductors can range from a few nanohenries to several microhenries, with tolerances that vary based on the application. Designers must select inductors with appropriate values and tolerances to ensure optimal circuit performance.

C. Types of Chip Inductors

1. Ferrite Core Inductors

Ferrite core inductors are commonly used in high-frequency applications due to their low core losses and high inductance values. They are ideal for power supply circuits and RF applications.

2. Air Core Inductors

Air core inductors, while less common in chip form, are used in applications where low inductance values and high-frequency performance are required. They have minimal core losses but may be larger than ferrite core inductors.

3. Multilayer Inductors

Multilayer inductors are constructed by stacking multiple layers of conductive and insulating materials. This design allows for higher inductance values in a compact form factor, making them suitable for space-constrained applications.

V. Working Principle of Chip Inductors

A. How Chip Inductors Store Energy

Chip inductors store energy in a magnetic field created by the flow of electric current through the inductor. When the current changes, the magnetic field collapses, inducing a voltage that opposes the change in current, thereby stabilizing the circuit.

B. The Role of Magnetic Fields

The magnetic field generated by the inductor is crucial for its operation. The strength of the magnetic field is proportional to the amount of current flowing through the inductor and the number of turns in the coil.

C. Impedance and Frequency Response

Chip inductors exhibit frequency-dependent impedance, which means their behavior changes with frequency. At higher frequencies, the inductive reactance increases, making them effective in filtering applications.

VI. Advantages of Chip Inductors

A. Space Efficiency

One of the primary advantages of chip inductors is their compact size, allowing for efficient use of space on PCBs. This is particularly important in modern electronics, where miniaturization is a key design goal.

B. High Performance and Reliability

Chip inductors are designed for high performance, with low DC resistance and minimal losses. Their reliability makes them suitable for critical applications in various industries.

C. Cost-Effectiveness

The manufacturing processes for chip inductors have become more efficient, leading to cost reductions. This makes them an attractive option for designers looking to balance performance and budget.

D. Versatility in Applications

Chip inductors can be used in a wide range of applications, from consumer electronics to industrial systems. Their versatility makes them a valuable component in many electronic designs.

VII. Limitations of Chip Inductors

A. Current Rating Limitations

Chip inductors have specific current ratings, and exceeding these ratings can lead to overheating and failure. Designers must carefully consider the current requirements of their circuits when selecting inductors.

B. Thermal Management Issues

Due to their compact size, chip inductors can generate heat during operation. Effective thermal management is essential to ensure reliable performance and prevent damage.

C. Frequency Limitations

While chip inductors are effective at many frequencies, they may have limitations at very high or very low frequencies. Designers must consider the frequency response of the inductor in their applications.

VIII. Applications of Chip Inductors

A. Consumer Electronics

1. Smartphones

Chip inductors are widely used in smartphones for power management, signal filtering, and RF applications, contributing to the overall performance and efficiency of these devices.

2. Laptops

In laptops, chip inductors play a crucial role in power supply circuits, ensuring stable voltage levels and efficient energy management.

B. Automotive Electronics

Chip inductors are increasingly used in automotive applications, including power management systems, infotainment systems, and advanced driver-assistance systems (ADAS).

C. Telecommunications

In telecommunications, chip inductors are essential for RF applications, signal processing, and power management in devices such as routers and base stations.

D. Industrial Applications

Chip inductors are utilized in various industrial applications, including automation systems, sensors, and control circuits, where reliability and performance are critical.

IX. Selecting the Right Chip Inductor

A. Key Parameters to Consider

1. Inductance Value

The inductance value is a critical parameter that must match the requirements of the circuit. Designers should refer to the circuit specifications to select the appropriate value.

2. DC Resistance

Low DC resistance is essential for minimizing power losses in the circuit. Designers should consider the resistance specifications when selecting chip inductors.

3. Current Rating

The current rating of the inductor must meet or exceed the maximum current expected in the application to ensure reliable operation.

B. Manufacturer Specifications and Datasheets

Consulting manufacturer specifications and datasheets is crucial for understanding the performance characteristics of chip inductors. These documents provide valuable information on inductance values, tolerances, and thermal performance.

C. Common Mistakes to Avoid

Designers should avoid common mistakes such as selecting inductors with insufficient current ratings, overlooking thermal management considerations, and failing to account for frequency response in their applications.

X. Future Trends in Chip Inductor Technology

A. Innovations in Materials and Design

As technology advances, new materials and design techniques are being developed to enhance the performance of chip inductors. Innovations in core materials and manufacturing processes are expected to lead to even smaller and more efficient inductors.

B. The Impact of Miniaturization

The trend toward miniaturization in electronics will continue to drive the development of chip inductors. As devices become smaller, the demand for compact and high-performance inductors will grow.

C. Emerging Applications in IoT and 5G Technologies

The rise of the Internet of Things (IoT) and 5G technologies presents new opportunities for chip inductors. These applications require efficient power management and signal processing, making chip inductors essential components in the next generation of electronic devices.

XI. Conclusion

In conclusion, chip inductors are vital components in modern electronics, offering space efficiency, high performance, and versatility across various applications. Understanding their construction, working principles, and selection criteria is essential for engineers and designers looking to optimize their electronic designs. As technology continues to evolve, chip inductors will play an increasingly important role in shaping the future of electronics. For those interested in delving deeper into this topic, further research and exploration of industry resources are encouraged.

XII. References

A. Suggested Reading Materials

- "Inductors and Transformers for Power Electronics" by W. G. Hurley and W. H. Spangler

- "Electronic Components: A Complete Reference for Project Builders" by Mark J. Balch

B. Relevant Industry Standards and Guidelines

- IPC-2221: Generic Standard on Printed Board Design

- IEC 60068: Environmental Testing

C. Online Resources for Further Exploration

- IEEE Xplore Digital Library

- Digi-Key Electronics Learning Center

This comprehensive guide provides a thorough understanding of chip inductors, their significance, and their applications in modern electronics. By grasping the fundamentals and staying informed about future trends, engineers and designers can make informed decisions in their electronic designs.